Wood textures: it’s all in the touch

from Daizen News 1 April 2012

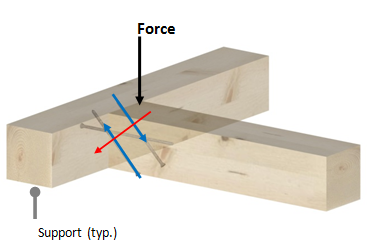

Even if two houses had the same floor plan, there are ways we could deliver a different feel to each frame. These include joinery design, of course, but also the finish surface of timbers. Finishing timbers seems such a, well, surface task. But when someone comes into a house and feels the wood of a post (and many people do this instinctively), the touch of the surface evokes one of their deepest responses.

Stain color has a lot to do with the timber surface, but the final texture is also key in delivering the result to match what you are

looking for. Daizen has five different timber surface finishes to respond to the variety in demand. From smooth to rough, they change the feel, literally, of the total frame.

Standard

The most common finish. Our timber is normally dressed in our four-sided planer to be exactly square and dimensional, but for the stain to penetrate into the fibre, the timber surface will require further treatment.

Super fine

Depending on how fine a finish is desired, it may be applied along with a finer-grid sanding, or we may use a hand planer to achieve the surface. This is our standard for “high-touch” applications like stairs or for anyone looking for finest surface quality.

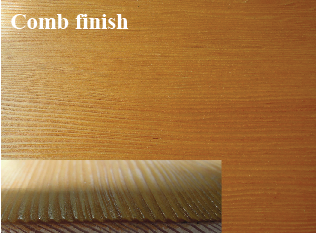

Comb finish

We raise the grain, for a patina effect to this finish. This is a great finish for those who want a bit of rustic feel yet desire a clean finish as well.

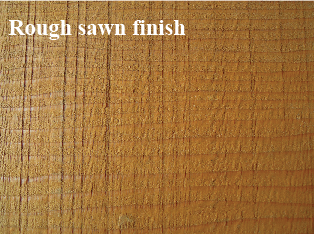

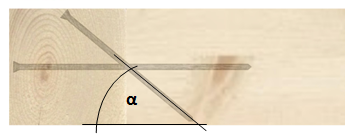

Rough sawn finish

Sawmill surface, for a true rustic feel. Rough sawn timbers are the only ones we can’t put in the planer, so the surface planes may not be totally square (common in traditional timber framing). This adds to the rustic feel. Joinery may be somewhat less tight in this finish, although structural integrity is never compromised.

Adze finish

The classic traditional finish, evoking a time before electric tools. We raise the grain, to give depth. A great finish for those who want a bit of rustic feel yet desire a clean finish as well. The faceted texture gives a warm, handmade feel.

Read More