From Daizen News September 2012

Our designer Kevin Mattson does all our timber frame design as well as production drawings. He lives at an off-grid site and raised his child, a son, in a 300-sq.-ft house. Living in a trailer on site, he built the house one part at a time, from 1991 to 2001. The house contains a full-size kitchen (the kitchen table is a dining table too), a living room on the opposite side, and a bathroom in the middle. Above the bathroom is the loft space that is Kevin’s bedroom; it had been a hideaway for his son for many years. Now Kevin’s young son, grown up and in Florida, is going to have a baby soon.

This is such a small house, but when I entered it, I was not able to draw the floor plan in my head for a while. Nice design.

On Kevin’s house, the posts are scribe-fit to rocks, exposed beams are protected with copper, natural light features prominently, and the walls are finished with textured drywall and good natural materials. Because it is small, Kevin can look after it very easily.

The entry is flanked by two natural posts scribed on to a rock base. The full-length wood shutters can be closed for both sunlight control and home security.

The front elevaton, with landscaping.

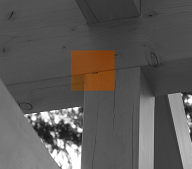

Interior view of the timber framed entry, enhanced with fixed picture windows. Light from the roof skylight is softened through the matchstick screens.

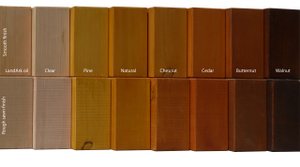

A driftwood ladder leads up into the loft bedroom. The bath is entered through a hidden door in the cedar paneling, to the right.

View from the bathroom looking through its [open] hidden door.

When in the glass shower in the bath, this is the view to the rear fern garden. Kevin can see the day’s temperature (posted on the tree) during his morning shower.

The kitecn, with its cherry cabinetry and black granite counters. Appliances include a propane refrigerator and stovetop, and a cast iron stove.

Kevin’s living room and home office. The triangular picture window includes an exterior awning shutter that can be operated from inside with a cable and marine hardware.

I visited a similar house in Oliver, B.C., designed by Henry Y. Mann (www.henryyorkemann.com/project/quietude). It’s a 350-sq.ft. house with everything its owner needs, including a full-size kitchen.

These people chose to live in quality. They are not rich but they spend time and money with deep thought down to every detail. They compromised on size, but every moment they spend in their space is suffused with satisfaction.

This is what Daizen wants to support. If your budget is tight, narrow your house down to a smaller area but build with high quality material and craftsmanship so that you and your loved ones can feel the joy of life at home. We can help you! Let us know.

Read More