Sharing knowledge at BC Wood

from Daizen News, 1 Nov 2011

The BC Wood Global Buyers Mission, September 8–10 in Whistler, B.C., was a productive conference. It’s an invitation-only networking and tradeshow event for international wood buyers and Canadian manufacturers.

Interested participants at the Daizen booth.

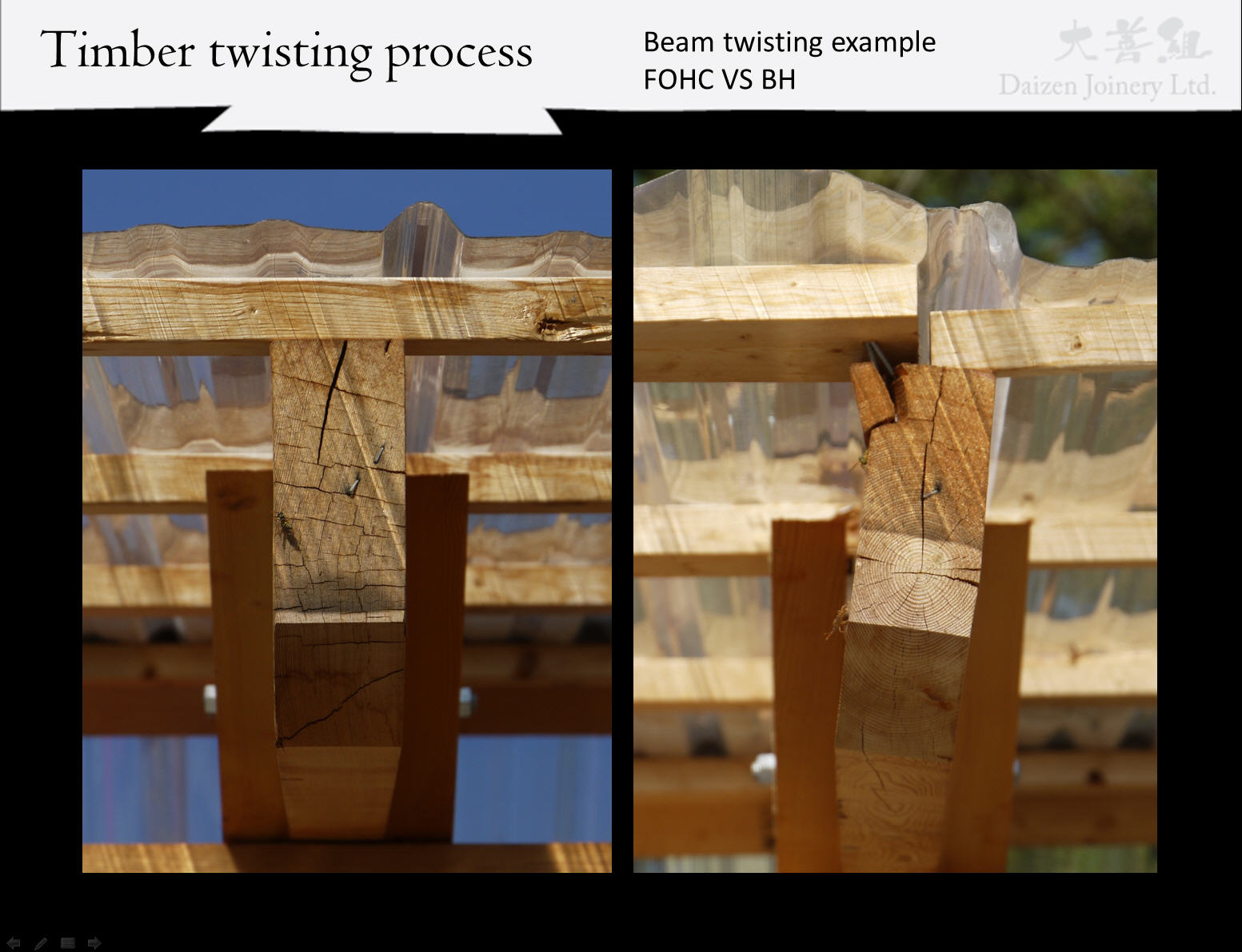

My presentation to architects was focused on why and how timber twists, and how we can control it. In my talk, I also compared glulam to kiln-dried timber, both of which I use. I clarified the optimal size and length of both glulam and kiln-dried wood (based on cost-effectivbeness) to use in timber designs for public buildings.

A twisted timber.

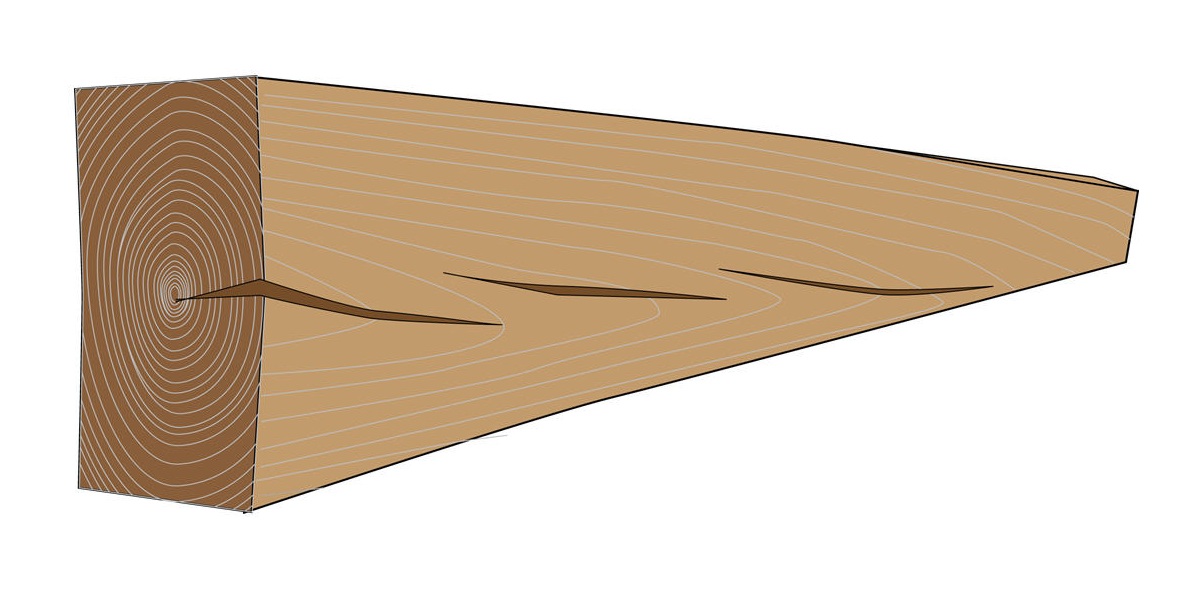

A log that has split.

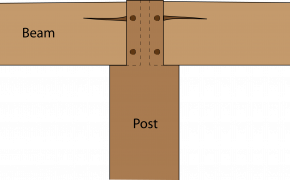

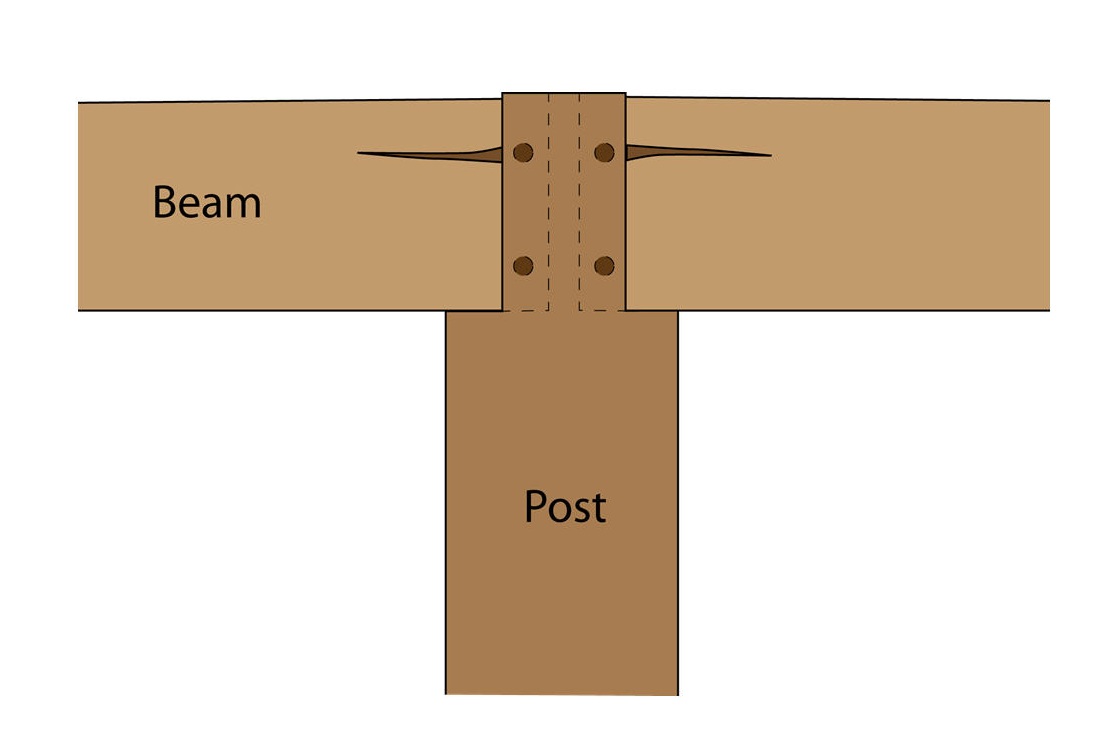

Shear at upper peg connection after timber has shrunk.

Read More