Dai goes to the source

From Daizen News 1 March 2012

Part of an exchange Dai had with Max Closen, of My-Ti-Con Timber Connectors.

“Hi Max, at December’s CWC engineer workshop in Kelowna, I was surprised by your placing of anchor screws from the main posts. I would always insert screws from the floor beam side, like a spike, but your method makes more sense.

I believe others think as I do. Can you explain for my readers why it’s better to send the anchor screw in from the main post that receives the floor beam?”—Dai

Max says,

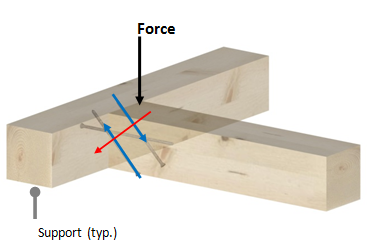

Here’s why. Fig. 1 below shows a typical joist-to-beam connection with ASSY structural wood screws installed at an angle. Installing screws on an angle uses their strongest property: withdrawal resistance.

Fig. 1. Insertion, at angles, of ASSY wood screws.

Commonly, screw-type fasteners are not driven into the wood on an angle but instead positioned perpendicular to a member’s surface. In perpendicular insertion, the weakest property of a screw-type fastener, its dowel action, is in force. A simple experiment can explain the difference.

Experiment:

- Take a ¼ x 4-in. wood screw and drive half of its length into the wood. Now bend the screw over. Notice how easy it was to bend the screw.

- Take a second screw and drive it into the wood under the same conditions. Now try to pull that screw out. As you saw, the screw didn’t want to come out from the wood. The same principle applies for the connection shown in Fig. 1, where the screw is driven in on an angle to the wood grain of the joist.

The two blue arrows in Fig. 1 indicate the correct direction for screw installation in order to maximize its capacity in this connection. The starting point of installation—whether from the top of the beam or the bottom of the joist—is up to the installer.

The red arrow indicates the least efficient installation direction. Installing the fastener as shown in red will not put the screw in tension and therefore will not use the screw’s high withdrawal resistance.

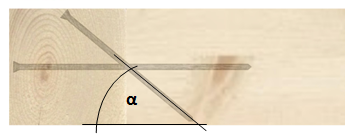

The range of the installation angle ![]() between the wood grain of the joist member and the screw axis is typically

between the wood grain of the joist member and the screw axis is typically ![]() (Fig. 2). Here you see an application of the basic trigonometric functions we all learned in high school (a2 + b2 = c2).

(Fig. 2). Here you see an application of the basic trigonometric functions we all learned in high school (a2 + b2 = c2).

I caution against installing screws at angles smaller than 30°. As the angle decreases between the wood grain and the fastener axis, end grain application occurs and reduced capacities must be considered.—Max

ASSY structural wood screws are made in Germany by SWG Production, a member of the WURTH Group. Statements made here are to the best knowledge and understanding of the author and shall be confirmed by the structural engineer of record of the project. My-Ti-Con Timber Connectors Inc. and its owners assume no liability.

Interested in finding out more?

At Daizen, we ensure client expectations and understanding of processes are met through all phases of our work, from structural design and engineering to fabrication of timber frames and assembly and installation.